Whether you provide a service with high operational demand on products and consumables or manufacture and need production logistics to keep everything running. We work hand in glove to ensure you keep focused on your core area of expertise.

If your operations are in the UK, we can help you innovate to reduce waste

Operational or production logistics is the strategic management of the flow of materials and resources within a service facility (e.g. hospitals within an NHS trusts) or production facility (e.g. Complex manufacturing environment). It encompasses all activities related to the movement, storage and handling of materials, from raw materials to finished goods.

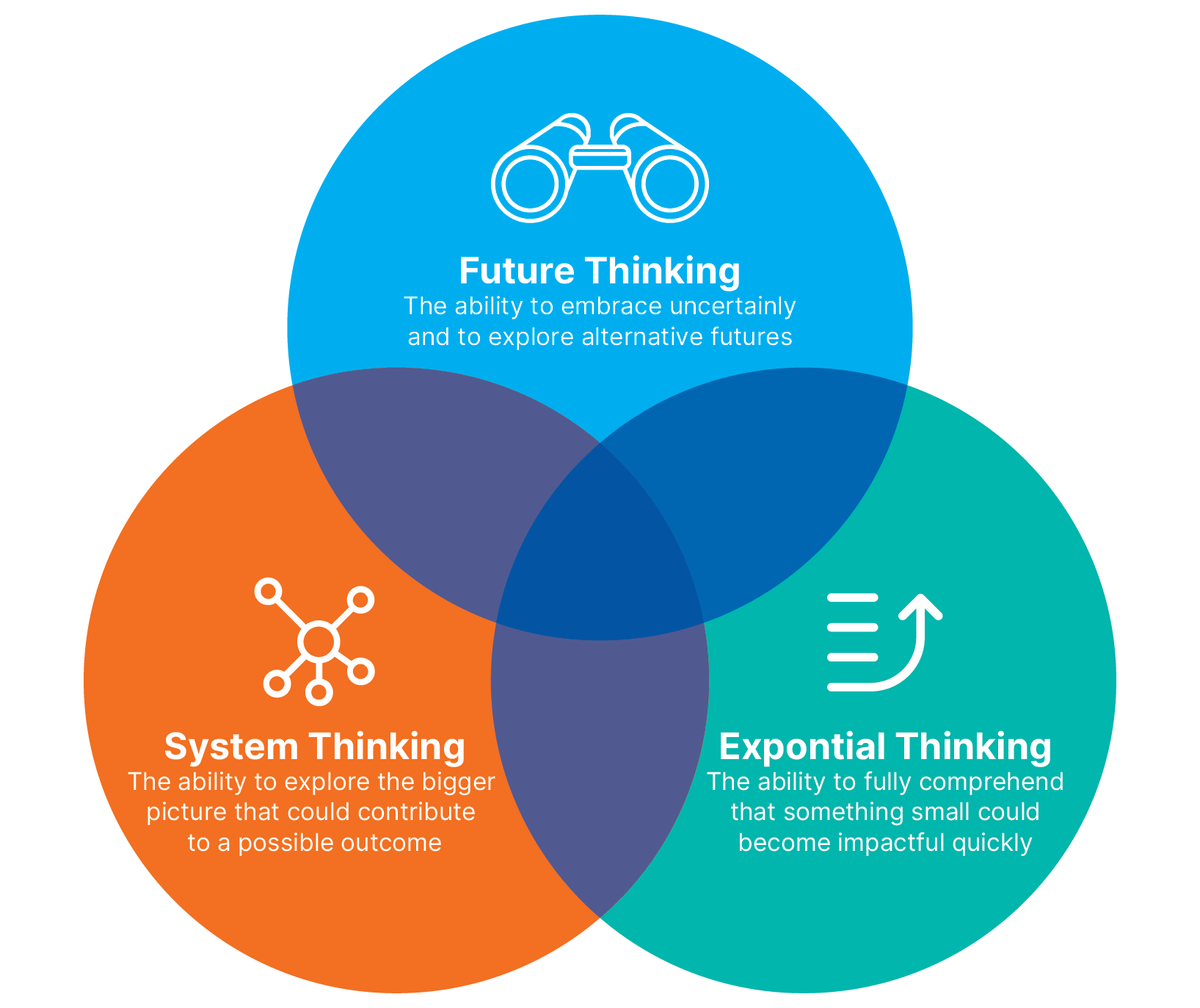

The goal of operational logistics is to create a smooth and efficient production process. By optimising material flow, reducing waste and improving productivity, organisations can enhance their competitiveness and profitability. Ensuring that all components and materials are where they need to be, exactly when they are needed.

We become a seamless extension of your organisation and work with you to achieve your goals.

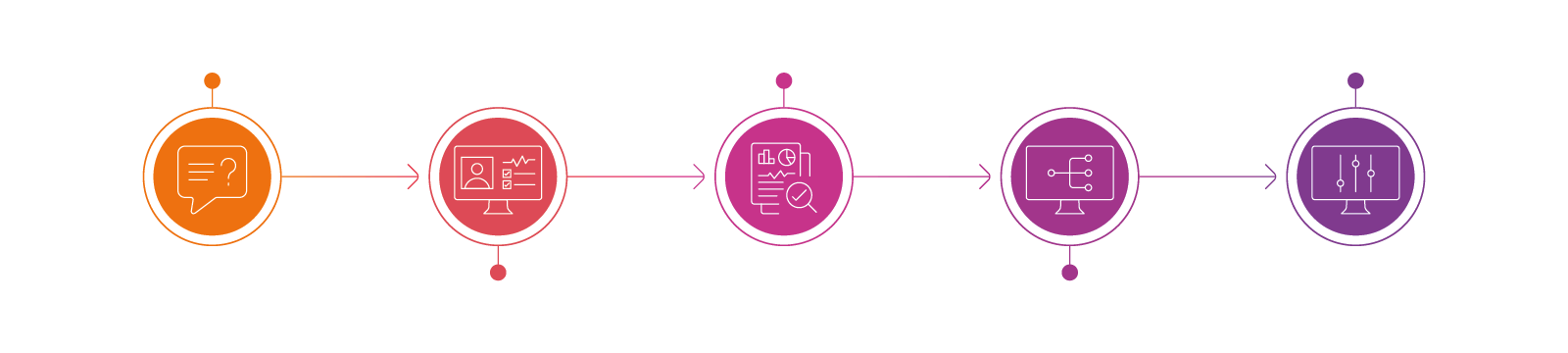

To ensure the optimal flow of materials throughout the value chain it’s imperative organisations remain agile, adaptive and receptive to change. There are five key areas in the journey towards operational excellence:

• Inbound: The management of goods delivered into a centralised facility, inventory control.

• Value Add: Warehousing, planning, control, consolidation, kitting/value add, monitoring and execution.

• Dynamic Feed: Efficient internal delivery of component elements to the relevant locations.

• Reverse: Integrated reverse flow of packaging from internal locations supporting circular supply chains and contributing to sustainability goals.

• Outbound: Preparation of finished goods or consolidated loads for onward distribution.

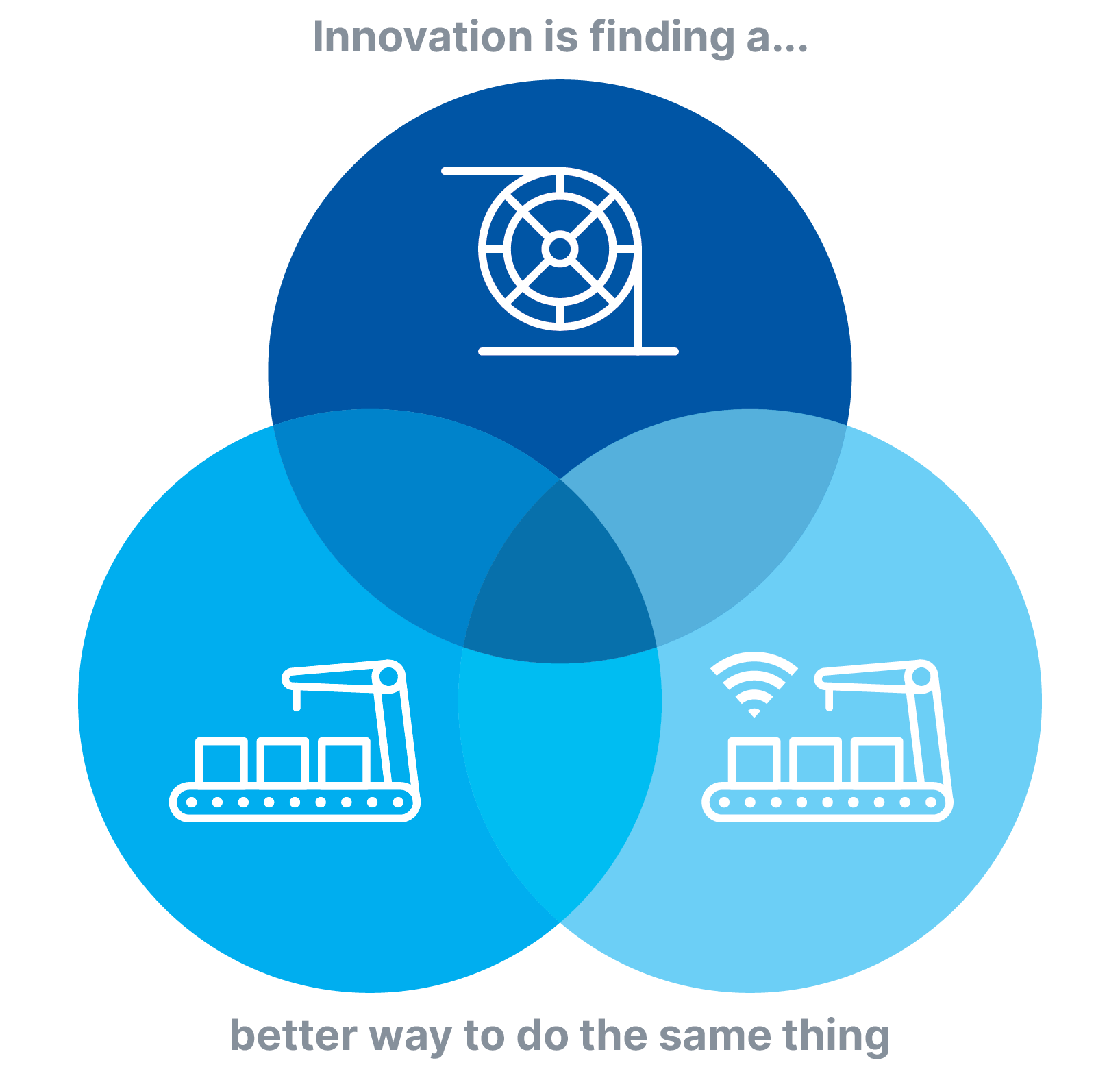

The journey towards operational excellence is marked by continuous improvement and relentless technological innovation.

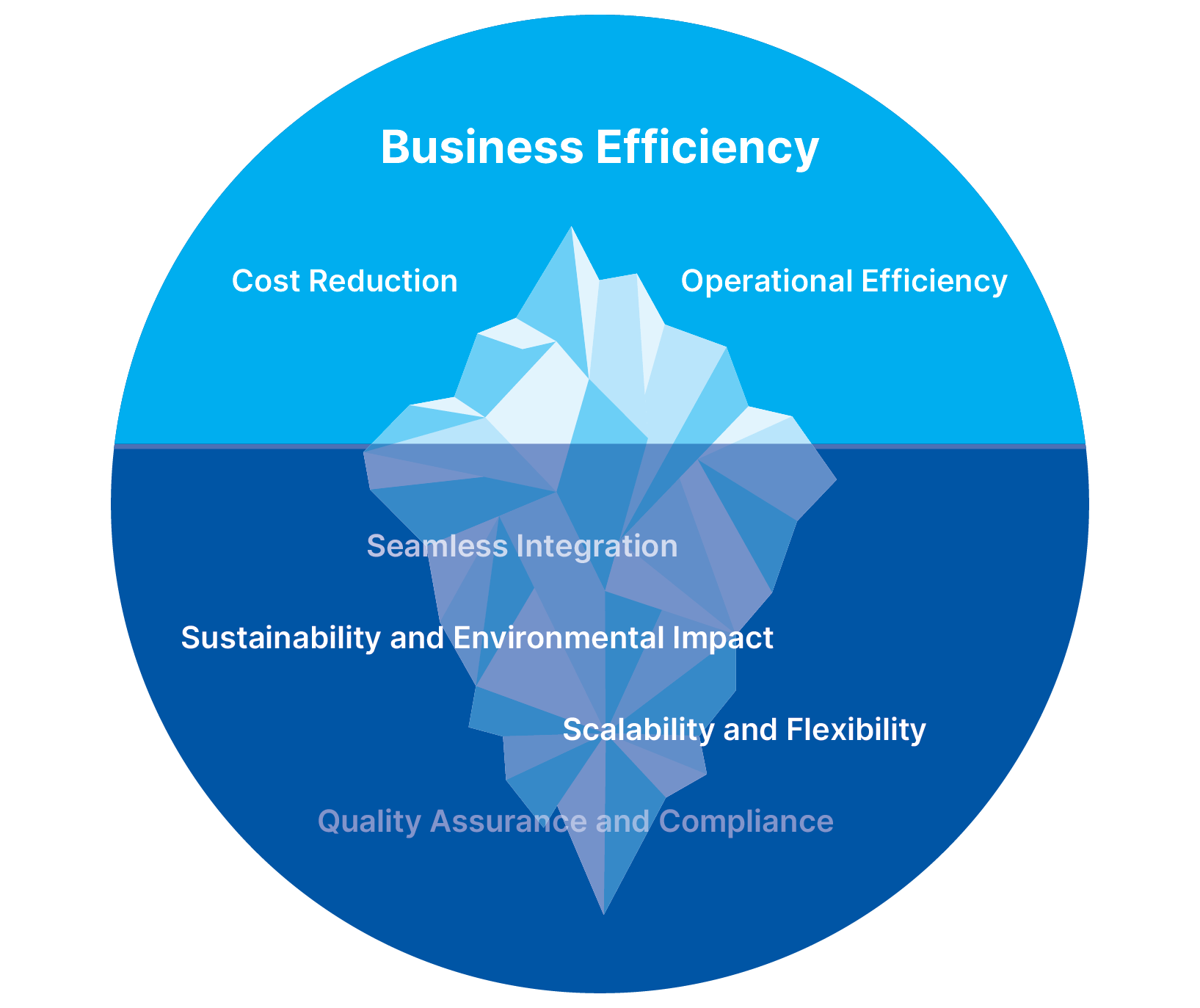

Rudolph and Hellmann can bring in-depth expertise to streamline operational or production logistics. As experts, we ensure that everything runs smoothly, efficiently and cost-effectively. Our deep understanding of production logistics allows us to design and manage workflows that minimise downtime, reduce bottlenecks and optimise resource utilisation.

Work closely with your teams to coordinate schedules, ensuring that all logistical aspects align with production timelines and goals. So just-in-time (JIT) logistics, ensure that materials and components arrive exactly when needed, reducing inventory costs and minimising waste.

Our experience can help you anticipate challenges and implement best practices, reducing risks and ensuring smooth operations. Working with advanced technology solutions for tracking, monitoring and optimising the supply chain, can offer greater visibility and control over your procurement logistics. Whether sourcing environmentally friendly materials or optimising logistics to reduce the carbon footprint of your supply chain activities.

Ensuring that the solutions provided are the most effective for the client’s unique operational context.

We provide solutions with options, a fixed transparent pricing structure and we give you a performance guarantee. We’ll take responsibility for delivering the solution and achieving the agreed cost saving, or we pay! We’ve proved ourselves in the most challenging manufacturing environments and we can help you identify and actively drive out cost from your supply chain operations.

What have you got to lose by starting a conversation?

Rudolph and Hellmann Crowned Enterprise of the Year at the Birmingham Signature Business Awards

© 2025 Rudolph and Hellmann Automotive | Website Design Quiet Storm Solutions Ltd